LG Chem HF380 Injection Moulding

Stephens Plastic Moulding Ltd is a plastic injection moulding solution provider in the UK.

LG Chem HF380 injection moulding

Stephens Plastic Moulding Ltd is a plastic injection moulding solution provider in the UK. Its headquarters is located in Birmingham, West Midland, and they have been in the industry for a couple of years. These years of experience that they have together with their modern types of machinery has made them some of the best plastic injection moulding service providers in the country. Moreover, this company offers services and products across different markets such as health and safety, medical, electronics, lighting, hygiene, and many more.

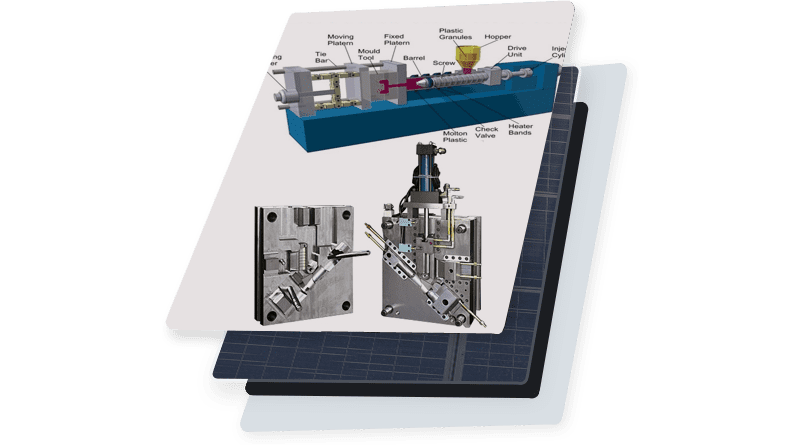

Injection moulding process

Technically, injection moulding is the process of creating parts by injecting molten materials. Different types of materials such as confections, elastomers, glasses, and metals are used in this process. Plastic Injection moulding requires a lot of precision and attention to details, which is what you will get when working with Stephens Plastic Moulding Ltd. If you are looking for someone who works with LG Chem HF380 material, then they are definitely the company that you should go to. They’re topnotch when it comes to their field, so you’ll never be disappointed with the services and products that they offer.

Requires a drying temperature

If you’re interested, the primary application for LG Chem HF380 injection moulding is for electronic products and miscellaneous goods. When handling this material, its injection moulding process should be precise because one little mistake can result in a lot of problems to the entire appliance component that it will be placed in. It is currently active in the commercial market and available in Asia, Latin America, Europe and North America.

The LG Chem HF380 injection moulding process requires a drying temperature between 70-80 ℃ and drying time between 2-4 hrs. Its minimum moisture content is -0.01%, and its melt temperature is around 210-240 ℃. Then, the mould temperature should be between 40-70 ℃ and processing it requires a back pressure hydraulic with 5-15 kg power and 30-60 rpm of screw speed.

Chem HF380 injection moulding

Stephens Plastic Moulding Ltd is up to the challenge of using the material LG Chem HF380 injection moulding. They have the experience and machinery to handle such material with precision and finesse. A testament of their high-quality work is the positive reviews they have gotten from previous clients who even until this day, only trust Stephens Plastic Moulding Ltd for the plastic moulding needs. If you’re not too sure where to get such services, you’ll surely never go wrong here.

If you want to know more about this company’s services and their processes for Chem HF380 injection moulding, you can give them a ring anytime, and they’ll get back to you as soon as they can.

When it comes to plastic moulding, Stephen Plastic Moulding Ltd is definitely second to none.

Their dedicated customer service representatives are more than willing to assist you in your inquiries and requests.

Plus, they’re not only friendly and respond quickly too, but they’re also very knowledgeable in their field, making them one of the most trustworthy sites today.