Acrylonitrile Butadiene Styrene

ABS, Acrylonitrile Butadiene Styrene (C8H8)x· (C4H6)y·(C3H3N)z) is an opaque thermoplastic with a glass transition temperature

Acrylonitrile Butadiene Styrene

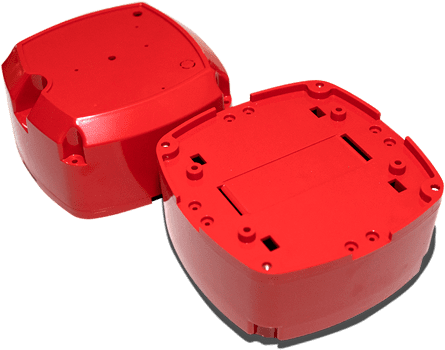

This strong, stiff and inexpensive plastic stands up well to external impacts and so is frequently used for protective packaging.

It is also easy to machine and can be painted, coloured, sanded, and glued, making it ideal for housings for power tools or cameras, which require varying textures.

ABS is a versatile, inexpensive thermoplastic which can be used in a wide variety of applications and has the great advantage that it can be recycled.

At Stephens Injection Moulding we frequently use ABS on its own or in combination with other thermoplastics

Our experienced team will be happy to advise you as to whether it is the right choice for your plastic injection moulding project.