Injection Moulding

Design Stage

Whether you just have an idea or are at a more advanced stage we provide a full design service to turn this into a product that can be plastic moulded.

“an idea – turned into a design ready for moulding”

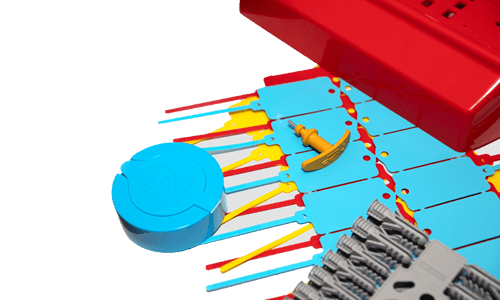

Aluminum Tooling

Aluminium tools are typically a lot quicker to produce and more cost effective when compared to steel tools.

“tools are made which are used to mould the design”

Samples / Prototypes

We are able to provide sample and prototypes to give you an idea of how the final product will look once injection moulded. Prototypes allow you test and plan – and if necessary fine tune the design before going ahead and investing in the tooling.

“a prototype allows you to see and test the product”

Steel Tooling

Steel tools take longer to produce and are more expensive when compared to Aluminium

“the tooling material depends on your requirements”

Injection Moulding

Once everything is in place we are ready for the plastic injection moulding.

If you are looking for plastic injection moulding we offer all the services that you need – contact us today for any advice or if you would like a free quotation.